Business corner cases can deplete your company’s resources at an astonishing rate; burying the information you need to make smart decisions, sapping the productivity and satisfaction of your employees, and whittling away at profits. This article explains what corner cases are, the burden they place on your business, the limitations of agentic AI to solve them, and how to conquer them with more sophisticated AI approaches.

Corner Cases & Workflow Process Gaps >

Software, Productivity, & Employee Workarounds >

Corner Cases & Enterprise Systems >

Introduction

Business corner cases are situations where a process, or parts of a process, are not accounted for in a company’s enterprise software solutions. They occur when there are changes to business processes after the software is launched, when the system is limited in scope due to resource constraints, or when they are intentionally left out because of their rarity or lack of budget impact.

Corner cases are encountered when the software can’t facilitate and track a necessary part of the workflow — causing a dead spot, or gap, in the data captured for that process. Because these “workflow process gaps”, as we refer to them, stem from seemingly low-priority activities, there is no particular urgency to address them within the software system. They’re normally handled on a case by case basis often using a workaround — a way of dealing with a problem without completely solving it. These workarounds typically do not send the data from the workflow back to the central enterprise systems.

As workflow process gaps multiply, they diminish productivity, inhibit business performance, and frustrate employees. They fly under the radar at most companies, invisibly eating away at profit margins like a pathogen because of the inefficiencies they create and the opportunities they indirectly cause to be lost.

In this article, we argue that corner cases, caused by workflow process gaps, are the barrier to productivity and growth in modern business. They are downplayed in most organizations, if they are acknowledged at all, and have expensive second order consequences that will eventually surface.

The solution we suggest is enterprise software transformation through AI augmentation. This solution could be applied to any enterprise software platform whose data can be accessed directly or through APIs, although ERP systems are the more obvious candidate due to their ubiquity and the large number of workflow process gaps they often intentionally ignore. ERP systems do not address most workflow process gaps, by design, because they are developed to meet the needs of the entire business.

During planning, resources typically allow for 20% of the effort to solve 80% of the issues; but rarely are there enough resources available to implement a solution for every use case in the enterprise. After the system is deployed, time, talent, and budgetary limitations usually put known corner cases on the back burner, negatively impacting the company’s ability to adapt to future market changes. In addition, the business evolves much faster than planned updates to the ERP, increasing the number of corner cases/workflow process gaps.

Unfortunately, agentic AI solutions are limited in their ability to solve corner cases as they typically can’t accumulate knowledge or improve over time. They also do not have reliable governance solutions and can’t be allowed to change enterprise data directly.

Corner Cases & Workflow Process Gaps

Corner cases, or workflow process gaps, arise when there is a misfit between process requirements and the company’s enterprise software. Workflow process gaps are relatively rare, difficult to anticipate, and typically complex. However once you see that they are workflows not captured by the enterprise ERP, every custom application, spreadsheet, or off the shelf system used for a specific division represents potentially lost data. It would be better if the data these systems captured could be recorded and processed centrally.

Workarounds are almost never static. At first, they’re implemented to bypass software whose planning did not foresee the use case so that a pressing problem can be solved. However, if the corner case isn’t a one time occurrence; the workaround remains in place and often ends up as a siloed standard operating procedure. When this is multiplied across dozens of departments and hundreds of employees, productivity suffers due to the difficulties in managing the adhoc data generated as well as the increasingly complicated workarounds.

Corner cases are the barrier to productivity in modern business because currently available enterprise software is not adaptable enough to address them within a relatively short period of time from when they occur.

The Gravity of Corner Cases

While lack of productivity is a massive drain on business performance and a barrier to market competitiveness, corner cases can have worse ramifications than that.

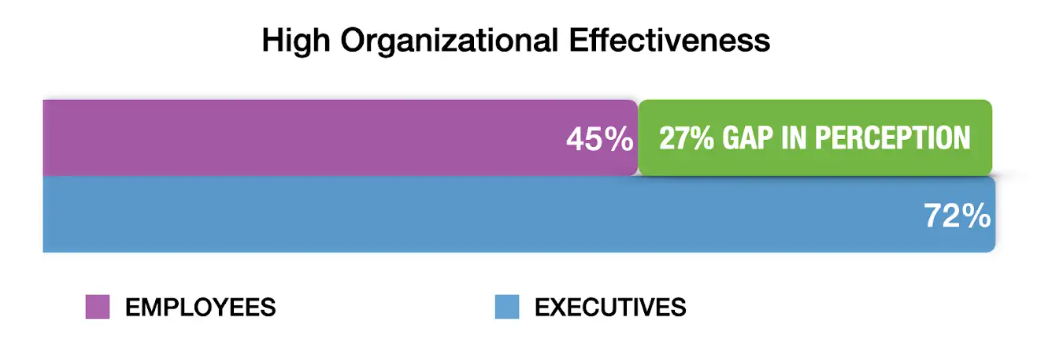

One of the biggest problems in turning a blind eye to workflow process gaps is that data “goes missing” at the enterprise level every time a workaround is used by a single department or employee and no others. When executives don’t have complete information, it results in a disconnect between C-suite executives and their employees and creates perceptual gaps in how the business is actually performing.

Released in May 2025, Terraform Leadership’s Org Effectiveness Index found that executives rate the effectiveness of their organizations 27% higher than employees do, suggesting that leaders believe the business is performing much better than it actually is. Eliminating workflow process gaps eliminates invisible data and allows executives to get the full picture of their company’s state of affairs.

Corner cases impact executives by hindering the company’s ability to adapt and innovate and by weakening its financial situation. They impact employees by reducing productivity and employee satisfaction. Solve corner cases, and you solve a whole host of other problems as well.

Software, Productivity, & Employee Workarounds

Software, productivity, and employee satisfaction are a troublesome trifecta to optimize. It’s similar to the dance that price, timeline, and quality do in project management; where conventional wisdom says that you can have two of the three, but not all three at the same time.

A 2022 study from the University of Iowa found that frustration with workplace hindrances made proactive people more likely to consider leaving their jobs. The more an employee self-identified as proactive, the more likely they were to consider quitting if they were regularly thwarted in accomplishing their goals at work.

There are many potential causes of frustration at work, but one of the most common is digital infrastructure and tool sets. Enterprise software fails employees when they encounter workflow process gaps — steps in the process that can’t be captured and recorded by the system. Proactive people will find a workaround, but they’re typically not happy about it. It’s inefficient, it slows them down, and it keeps them from achieving their goals.

Software

Because there has not historically been the technology and resources to do everything, most software platforms in use today intentionally do not solve for every scenario. Instead, they use the Pareto Principle, more commonly known as the 80/20 rule. It can be articulated in two ways: 20% of the features will be so difficult to implement that they will take 80% of the budget or conversely 20% of developers’ time is spent on work that addresses 80% of use cases.

In order to move from a zero-sum mindset to a synergistic one, the 80/20 rule needs to be made unnecessary. With the current limits on technology and resources, limiting software features is a reasonable thing to do. If correctly implemented, AI augmentation of enterprise software has the potential to overcome these limitations.

Productivity

Ever since The Principles of Scientific Management was published in 1909, Americans have been spilling a lot of ink about workplace productivity, which means it now has hundreds of meanings and connotations. In this article, we will be limiting ourselves to a very specific hindrance to productivity, workarounds necessitated by intentionally rigid enterprise software.

Obstructed productivity is a strain on proactive employees and bad for the business. In a 2022 study of digital workplace productivity, employees reported that they were performing at 60% of their potential productivity and estimated that they could be 22% more productive with the right software systems. If that is anywhere close to being true, the lost potential is staggering.

Enterprise software is shipped with the promise of increased productivity, streamlined operations, and real-time analytics. Yet too many organizations still have people:

- Entering the same data in multiple places

- Finding and using their own software solutions, whether it’s allowed or not

- Keeping organizational data in filing cabinets

- Developing unique workflows for themselves or their departments

- Storing and manipulating data on spreadsheets or paper

- Unable to enter new kinds of data, or levels of granularity, based on business activities

These behaviors continue, in part, because the software is necessarily rigid in order to enforce business and security rules; but also because it’s unable to execute complex, multistep workflows. Most productivity problems are created because the system can’t deal with workflow process gaps, or because it’s too much trouble to customize it for them. As the business environment becomes more complex, corner cases multiply and addressing them becomes time consuming, tedious and requires a large expenditure of time.

From the CIO’s perspective, workflow process gaps aren’t a problem. The system wasn’t designed to handle them and that’s that. Workarounds often aren’t viewed as a problem either because employees are perceived to eventually get their work done. It isn’t until the company wants to scale, grow, or adopt new procedures that workflow process gaps and their associated workarounds become an obvious issue at the C level.

Managers have a different point of view since an increasing amount of their time, and the time of their senior staff, is taken up maintaining these corner cases which often involve spreadsheets, orphaned databases or even hand-written notes for non-standard workflows. They feel the productivity hit on a daily basis.

Employee Workarounds

In 2022, a research paper was published that explored how employees behave when faced with information systems that inadequately support their work (Wong et al. (2022)). The literature review prior to it provides some excellent insights.

In addition to confirming the problems most astute observers have already noticed with workarounds (silos, inefficiencies, unreliable data), the authors make a strong case that workarounds are the result of coping behavior. In response to demands that exceed their resources, employees have two choices: resign themselves to the situation or persevere to find a solution: almost always a workaround.

Using workarounds as a coping mechanism negatively impacts employee satisfaction through loss of confidence in the system, fears about making a mistake, and the extra time it takes to get the job done. The following examples are warning signs that those employees who are not able to resign themselves to the situation could be on their way out:

- Tracking orders outside the platform because they can’t get relevant information on demand from the corporate enterprise system

- Creating an independent system of order cancellation and rescheduling so they have enough control to ensure clients’ needs are met

- Using a personal phone app for delivery coordination because without it something would fall through the cracks

Software, productivity, and employee satisfaction converge at a critical point in the enterprise and their relationship should be synergistic: producing a combined effect greater than the sum of their individual contributions. It has to begin with the software though. Get that right and both productivity and employee satisfaction will improve. Do nothing and the situation deteriorates, often in subtle and hidden ways. Once the problem is obvious to everyone, it may be too late to make up for lost time.

Corner Cases & Enterprise Systems

In a recent article for ERPNews, Atigro CEO Ken Fischer wrote, “Corner cases can be generated in both negative and positive scenarios. Unanticipated problems can arise from a spectrum of business operations – customer service, manufacturing, asset management, billing, supply chain management, and procurement, among many other areas. They can also arise from business opportunities that stem from entering new markets, customer wins, and business partnerships, to name a few.”

He goes on to discuss how enterprise software systems are necessarily rigid, rendering them unable to easily address workflow process gaps and causing data to be lost or underreported (emphasis mine). Not having access to accurate, trustworthy data is the root cause of a number of negative business outcomes such as late shipments, too much or too little inventory, missed business opportunities, declining revenue, and so on.

Examples of Corner Cases & Their Workarounds

In order to understand corner cases and the impact they can have on operations, it’s useful to look at some concrete examples. The following cases are taken from real-life business situations. More importantly though, with the right software system, they can be quickly resolved without a workaround.

Equipment Rentals

For large companies in industries such as construction, mining, energy, and agriculture; equipment management at job sites has long, complex processes. They may have hundreds of types of equipment, at locations in multiple states, where some pieces of equipment can only be ordered from certain states due to logistic complexity or local demand. The equipment usually needs to be delivered and picked up in a way which optimizes both maintenance and logistic processes..

Scenario 1

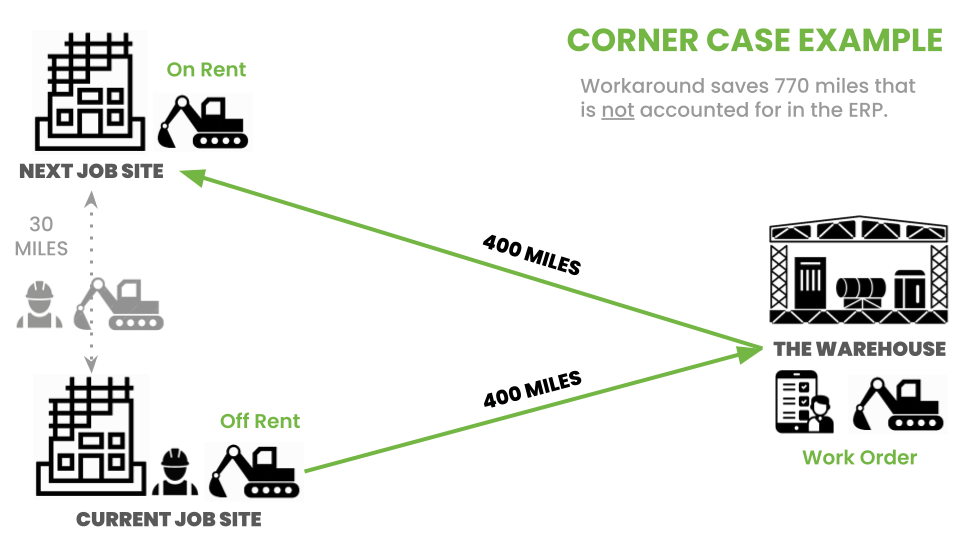

Process: When a piece of equipment is required for a job, it is requested from the warehouse, sent to the job, and put on rent. After the job is complete, the equipment goes off rent, is picked up and returned to the warehouse, and a work order is created to inspect it and confirm that it is in good condition and can be rented out again.

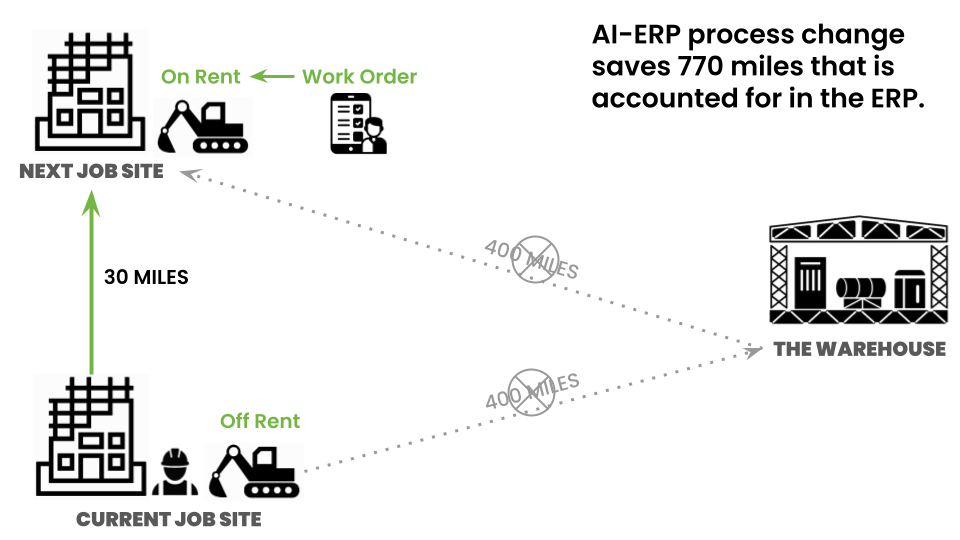

Situation: A second job needs a piece of equipment already onsite at another job as soon as the equipment goes off rent at the first job. Both jobs are 400 miles away from the warehouse but only 30 miles away from each other. Bringing the equipment back to the warehouse before taking it to the second job will entail an unnecessary 800 mile round trip and it is relatively inexpensive to have the equipment inspected onsite.

Corner Case/Workflow Process Gap: The software system doesn’t have a way to adjust the process to send the equipment directly to the second job without bringing it back to the warehouse and completing the inspection work order there.

Workaround: A technician visits the original job site on a weekly basis. Working outside the platform and the process, he completes the inspection work order at one of the job sites and transports the equipment from job 1 to job 2 directly instead of taking it back to the yard: saving hours of time and gallons of fuel in the process. The paperwork and what has been put in the system don’t accurately reflect any of this, so executives are left in the dark and cost accounting is inaccurate.

What The Right Technology Could Do: AI systems that augment new or legacy software platforms can be instructed by an authorized user to move the equipment from job 1 to job 2 and complete the work order at one of the job sites in a way which is compliant with all business and security rules regarding the movement of equipment and cost calculations.

Scenario 2

Process: When a single piece of equipment requires assembly before being utilized, the reservation and delivery process needs multiple delivery tickets and an assembly ticket to track the delay from the time the equipment is delivered til the time it becomes usable. The assembly ticket is completed after the equipment is delivered and the modular goes on rent. To terminate the reservation, similarly a disassembly ticket is created and multiple equipment pick-up tickets are created. Once the disassembly ticket is marked complete, the equipment status is updated to off rent even though the pieces are still at the job

Situation: Equipment which is not classified as a “modular” needs to be handled in the same way for some jobs.

Corner Case/Workflow Process Gap: The software system is unable to execute this process for equipment that is not classified as a modular or trailer.

Workaround: Employees schedule the outliers outside of the software system. A software update is in the works to enable it to handle the new scenario, but that process takes time. Until then, executives don’t know where their equipment is or what condition it’s in.

What The Right Technology Could Do: AI systems that augment new or legacy software platforms can be instructed by an authorized user to execute the process with any new piece of equipment.

Billing

Large national companies have a complex web of tax scenarios to manage. Because zip code boundaries are set by the U.S.P.S and tax jurisdictions are created by states, counties, and municipalities, the same zip code can have different tax rates. Some jobs are taxable and some aren’t. It’s a perfect recipe for corner cases.

Situation: Occasionally, jobs which aren’t taxable are mistakenly taxed. When that happens a credit must be issued for the taxes and the state tax report needs to be updated.

Corner Case/Workflow Process Gap: The software system is unable to credit the taxes back or update the state tax report with the amount of the credit.

Workaround: Because the database needs to be manually updated when this happens which requires the assistance of a SQL admin, employees resort to adjusting the tax rates in excel. The software invoicing system could be modified to allow for the credit to be added, for it to have a billing code, and for it to recognize what the billing code is. This is more complex than it sounds because it requires modifying the rules for creating invoices, adding data to the billing code list, and flagging it to be returned to the state tax report. These types of customizations can be done, but it can also feel like being nibbled to death by ducks.

What The Right Technology Could Do: AI systems that augment new or legacy software platforms can be instructed by an authorized user to adjust the invoicing coding process and update the code.

Corner cases like these could be resolved by augmenting enterprise software systems with networks of AI-powered modules that solve complex problems by dynamically interacting with people, databases and specialized tools in the software. They could accept requests from employees and access information from databases and other data sources, solve tasks, and provide results in an easy to consume manner. The possibilities for increasing productivity and engaging employees are literally endless.

Agentic AI Cannot Solve Corner Cases Well

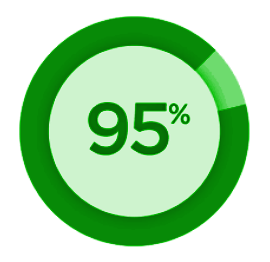

Before getting into how AI augmentation could resolve issues with workflow process gaps, it’s important to understand the current status of corporate AI adoption: it’s failing to deliver ROI 95% of the time. That’s the bad news. The good news is that there are specific, actionable reasons why.

A July 2025 report from the MIT Media Lab’s Project NANDA found that 95% of AI business initiatives fail to generate a positive return on investment. Some of the reasons for these failures are pertinent to this discussion of corner cases.

- Strategic misalignment of spending. Companies are spending most of their money on sales and marketing when higher returns are realized from back office initiatives.

- Generative AI limitations. According to the report, “Most GenAI systems do not retain feedback, adapt to context, or improve over time.” with one interviewee saying, “For high-stakes work, I need a system that accumulates knowledge and improves over time.”

- Favoring in-house development. AI solutions from specialized external vendors succeed 67% of the time, compared to a 33% success rate with internally built tools.

A more sophisticated AI augmentation is needed to address each of these three reasons for failure.

- It was developed specifically for back office operations such as logistics, supply chain management, finance and accounting, human resources, and operations management.

- Its networks of AI-powered modules can solve complex problems, incorporate self-learning, and improve over time, allowing it to overcome the limitations of generative AI and escape its gravitational pull.

- It must be built by AI experts. Unlike an in-house team, they don’t have multiple priorities vying for their attention. External AI experts can focus on AI augmented enterprise software 100% of the time.

This is not agentic AIbut a more sophisticated AI-powered module that can use known problem-solving strategies to solve known types of problems in enterprise software solutions such as ERPs, SCMs, HRMs, to name a few. A 95% failure rate doesn’t have to be a foregone conclusion.

“When done correctly, by AI systems that augment new or legacy ERPs, these revitalized assets could effectively address the growing number of corner cases a business generates or encounters. Additionally, the AI system could ensure that the new data can be connected to legacy data, documentation is maintained, and all of it follows business and security rules. The power of quickly addressing ERP corner cases rests in delivering a single, flexible interface. The cost of and speed of adding that flexible interface to the ERP is much easier to rationalize compared to individual customizations for individual corner cases.” (ERP News)

Revisiting Equipment Logistics with AI Augmentation

In the first example, we’ll look at transporting two telehandlers: hydraulic lifting machines used to carry and place heavy materials. This task is routine. In the second example, we’ll look at a corner case and see how the software’s problem solving capabilities could process and complete it as easily as a routine case.

Example 1

The AI augmented software system is an ERP. The task that has been given to the AI-ERP solution is to “move two telehandlers from the yard to a specific job site”. While it seems like a simple query on the surface, a closer look reveals the following variables and dependencies:

- Which telehandlers need to be moved? No descriptions or model numbers were given.

- Do any of the telehandlers have open work orders?

- If so, should the repairs be made and the work order closed before the equipment is moved?

- Some repairs are more serious than others. Is it okay to move a dented piece of equipment without closing the work order? What about a piece of equipment with a cracked window?

- Are all the necessary parts in stock?

The employee and the AI-augmented ERP interact with each other to complete the task. The employee makes the request in natural language as if he were talking to another person. The AI-ERP recognizes that the employee didn’t specify which telehandlers were to be delivered to the job site, produces a list of those that are available, and asks him which ones should be moved. The answer can be given in any choice of words: first and last, number one and number two, or anything else that comes to mind. The system then updates the original query with the equipment ID numbers.

If the telehandler has an open work order, the AI-ERP will evaluate the severity of the damage and make a recommendation to the employee about repairing it before moving it. If both are damaged, it can determine that a dent doesn’t need to be repaired before being delivered, but a broken window does. Once all the dependencies have been resolved, the system ends the communication with the employee.

Example 2

For this example, let’s revisit the workflow process gaps in Scenario 1 under Equipment Rentals: “The software system doesn’t have a way to adjust the process to send the equipment to the second job without bringing it into the yard and completing the inspection work order there.” Remember, the AI-ERP knows and follows all business and security rules.

The AI-augmented software system is again an ERP. The employee tells the AI-ERP to take the piece of equipment that is at job site A off rent, transport it to job site B, and open a work order. It can recognize that the technician assigned to the site should be assigned responsibility for the transfer and for completing the work order, and check to see when she is available to complete those two tasks. Once the work order is closed the AI-ERP will place the equipment on rent at the new job site. All of this is done in a matter of seconds, and doesn’t require conversations or coordination among the staff.

In addition, users with permission to do so may update the business rules so that the next time this situation arises, the AI-ERP will know that the equipment can be sent directly to the second job site and repaired there before going on rent.

AI Augmented Enterprise Software is the Solution

Businesses are becoming more complex, and at the same time their growth goals are becoming more ambitious. This has caused the number and type of corner cases to burgeon in the 21st century.

Because enterprise software systems aren’t inherently flexible, customizing them to handle issues that seldom occur rarely makes financial sense. This leaves employees to come up with their own solutions which, to be frank, can work more efficiently than the legacy software at first. However, there are hits to productivity, both when the workaround needs to be created and as it needs to be maintained over the years. In the worst case scenario, the workaround becomes a normal part of business operations and the company learns that it can’t scale for growth without addressing it.

Using workarounds to address workflow process gaps also takes a toll on employee satisfaction. When workers feel like their ability to perform at their highest level is hampered by outdated systems, they become frustrated and start looking for someplace else to work. The combined drains on productivity and employee retention are like competing in a race with ankle weights.

Finally, workarounds “disappear” data from the system, resulting in a mismatch between how executives believe the company is performing and its performance in real life.

The good news is that these challenges could be overcome with AI-augmented enterprise software that is more sophisticated than agentic AI approaches allow. Businesses don’t need to get rid of their legacy systems or undergo expensive transformations. The augmented system could network AI modules in a way that easily accommodates corner cases without losing information or accumulating inaccuracies. Ambitious, growing companies no longer need to settle for something that imperfectly meets their needs and doesn’t scale with growth.

About Atigro

Atigro is a proven ERP transformation firm that pairs its modular augmentation capabilities with AI-native frameworks. Atigro’s experience and capabilities generate the rapid development and provisioning of new ERP functionality that meets dynamically changing business processes.